This is evidence to show a water fitting is of an appropriate quality and standard for installation.

Water undertakers will consider evidence of compliance provided on a case and site specific basis.

Whilst this evidence must satisfy another regulation/byelaw [4(2)], water undertakers have no preference for, or require it to be in a specific form. Typically, they will consider declarations of performance issued against designated standards, product certification and test reports.

Please note:

Because a water fitting must comply with all parts of the regulations being of an appropriate quality and standard does not, of itself, guarantee compliance with the regulations.

The latest available edition or version of guidance or specifications should always be used.

In respect of equivalence water undertaker retain absolute discretion in assessing whether a national specification provides an equivalent level of protection and performance to that specified in an appropriate British Standard. For information regarding the equivalence of a performance specification please contact your water undertaker.

For further information please refer to Regulation 4(1)(a) compliance guidance and BS 6920 Compliance Overview.

Any questions please contact the local water undertaker for advice.

Establishing whether a water fitting is suitable for installation is dependent upon a number of factors including but not limited to:

Water fittings must be of an appropriate quality and standard

System design, things considered include but are not limited to compatibility:

with other water fittings within a plumbing system (e.g the potential for galvanic action)

system operational parameters (e.g. the maximum* and minimum pressure, temperature and flow the systems will be operating at)

Location specific factors, things considered include but are not limited to:

the environment (e.g. ground or airborne contamination, the risk of frost damage, corrosion or dezincification)

product installation requirements and/or constraints (e.g. installed where light is excluded or only above ground)

installation backflow risks (e.g. the need for backflow protection to be installed)

Requirements of schedule 2 as applicable.

If the proposed plumbing work is notifiable, the suitability of water fittings will be assessed as part of the notification process.

If the installation is not notifiable there remains a legal obligation for the installer and premises owner or occupier to ensure the plumbing work is fully compliant with the water fittings regulations in England, Wales and Northern Ireland, byelaws in Scotland. Therefore, if in doubt, contact the local water undertaker for advice.

*Please note all water fittings must be capable of withstanding an internal water pressure of not less than 1½ times the maximum pressure it will be subject to in operation.

Providing appropriate and adequate backflow protection against the highest level of risk downstream is installed, an installation not used to supply water for drinking, bathing, food preparation or cooking purposes is exempt from complying with schedule 2 paragraph 2(1).

Please note the backflow protection required needs to be assessed by the local water undertaker and other requirements of the water fittings regulations/byelaws continue to apply.

When designing a compliant plumbing system a number of factors need to be considered, including but not limited to:

Avoiding the risk of contamination or damage resulting from the environment in which the system is to be installed or due to the design itself.

The required and attainable supply pressure and other operational parameters

User expectations and whether these are achievable

Suitability of water fittings for use

Providing appropriate, adequate backflow protection.

Water efficiency

Limiting waste.

Useful sources of information include BS EN 806 and BS 8558

To help prevent waste and contamination all pipe and fittings systems must be of an appropriate quality and standard and suitable for the circumstances in which they will be used.

Before installing a pipe and fittings system key considerations will include but are not limited to:

The compatibility of the pipe and fittings. For example, to ensure connections are watertight and configured to prevent galvanic action.

Whether the pipework is to be installed above or below ground

Where the pipework is to be installed. For example, in contaminated ground, in a duct and potentially exposed to construction materials and/or water vapour, somewhere exposed to sunlight or sources of heat.

What water temperatures and pressures the pipework will be exposed to. For example, hot or cold water only, heating systems, maximum operating pressure and thermal shock.

In the case of metallic water fittings, the possibility of corrosion due to galvanic action and dezincification.

Useful sources of information include BS EN 806 and BS 8558

Please note:

All water fittings should be resistant to corrosion. In the case of mechanical backflow prevention devices and metallic fittings which are not going to be readily accessible, in addition to being corrosion resistant these should be manufactured from materials which are not susceptible to dezincification. For example, gunmetal or CR brass.

As non-metallic pipe and fittings can be affected by sunlight and/or allow ingress of light, which is known to promote the growth of algae, consideration should be given to whether protective measures to exclude light are necessary.

Adhesive joints are not acceptable below ground.

Irrespective of what fluid is being conveyed all pipework, whether installed above or below ground, should be marked in accordance with the latest version of BS 1710.

To identify what parts of a plumbing system they control, servicing valves should be labelled.

For further information please refer to the pipe identification information leaflet

One way is to measure the supply pressure at a tap directly supplied from the mains at a time when there is little demand, such as at night.

Please note:

This will not take into consideration any transient or surge pressures which may be generated within the system. For example water hammer resulting from the rapid closure of a valve within the system.

Water fittings must be able of accommodating 1½ times the maximum operating pressure.

‘Dead leg’ or ‘blind end’ is a term used to describe a section of pipework (leg) containing water which is not turned over i.e. the water is stagnant (dead). For example, pipework which supplied a system that has been removed or is no longer in use (redundant).

Dead legs should be removed as they are a potential source of contamination. If the dead leg cannot be completely removed any blind end should be as short as possible.

All plumbing systems should be designed to ensure a steady through flow of water. For pipework supplying fittings which are used infrequently i.e. fire supplies or water reuse systems with a back-up supply, appropriate backflow protection should be installed as close as reasonably practicable to the mains or supply/distributing pipe.

Yes.

The pressure testing requirements specified in BS EN 806 recommends that plumbing installations and fittings be tested at 1.1 times the maximum working pressure rather than the 1.5 times required by the Water Supply (Water Fittings) Regulations, Byelaws in Scotland.

However due to the terms and definitions applied rather than advocating a lower pressure test than that required by the UK national requirements BS EN 806 actually recommends a slightly higher test pressure. With the result that should an installation be designed to satisfy the pressure test recommendations given in BS EN 806, then it will by default comply with those of the Water Fittings Regulations /Byelaws

Summary of requirements of BS EN 806:

BS EN 806: Part 1 defines maximum design pressure (MDP) of a system as:-

‘the maximum hydrostatic pressure at which the potable water installation is designed to work’

BS EN 806: Part 2 covers design, clause 3.4.2 which covers strength states:-

‘To ensure adequate strength, all components of the system shall be designed to meet the test pressure requirements of the local and national laws and regulations. The test pressure shall be at least 1.5 times the allowable maximum operating pressure (PMA).’

Therefore the maximum design pressure should be at least 1.5 times the maximum operating pressure.

MDP = 1.5 x maximum operating pressure

To comply with the requirements of schedule 2 paragraph 15 (1) a backflow prevention device or arrangement rated to at least fluid category 2 must be installed Fittings Regulations/Byelaws require the system to be pressure tested at:-

1½ x 5 bar =7.5 bar

BS EN 806 recommends a test pressure of:-

1.1 x maximum design pressure (MDP)

where

MDP = 1½ x maximum operating pressure

1.1 x [1½ x 5 bar] = 8.25 bar

Good system design, commissioning and maintenance will help to reduce and address the risk of contamination resulting from microbial growth and limit waste due to taps left to run.

Storage and distribution temperature requirement for domestic hot water systems are set out in other legislation, codes of practice and British Standards.

For further information please refer to Building Regulations, BS EN 806, BS 8558, HSC L8 and CIBSE Commissioning Code M.

The risk is dependent upon the fluid, for example, the dose used and concentration of inhibitors within the system. The volume of fluids and operating pressures will also be considered when assessing the suitability of the backflow protection device or arrangement to be installed.

Please note the final decision rests with the local water undertaker.

Yes, appropriate separation is required. Minimising the risk of contaminated fluids coming into contact with water to be used for domestic purposes (drinking, bathing, washing, cooking etc) is a key objective of the water fittings regulations/byelaws.

Mindful of the need to ensure sufficient safeguards are in place to address the possibility of drinking water supplies coming into contact with fluids which are not considered to be wholesome, in determining whether systems making use of heat recovery or exchange are compliant with regulation 4(1) the following factors will be taken into consideration. Please note decisions will be taken on a case by case basis.

The actual fluid categories of the fluids within the system.

How readily identifiable any potential integrity failure of the system would be.

Whether the system design meets the requirements for single or double wall separation specified in BS EN 1717.

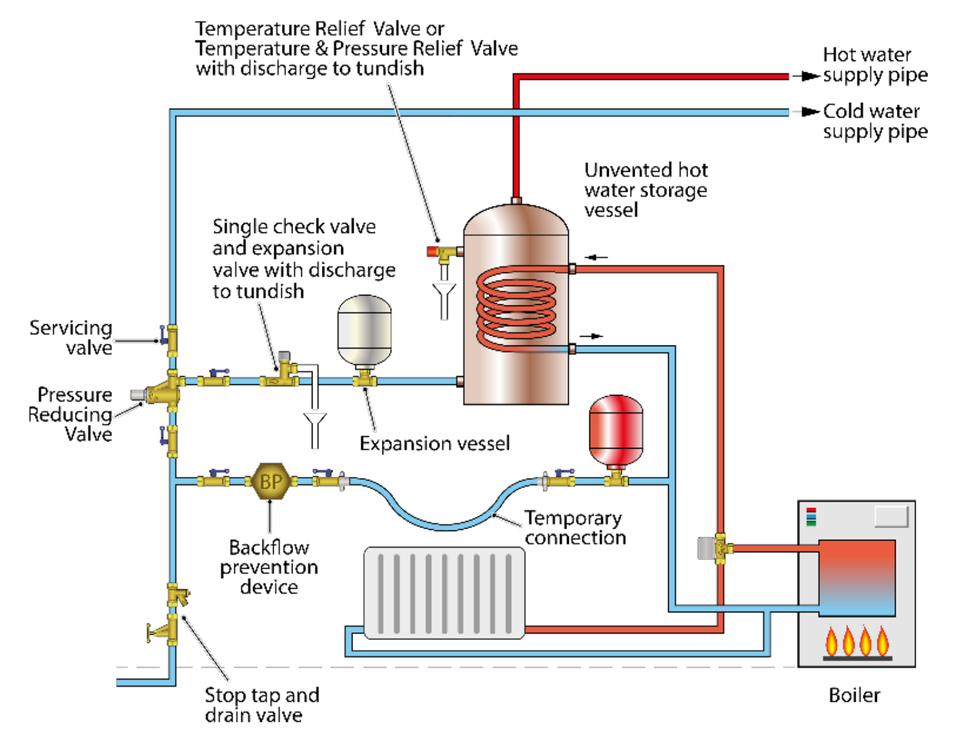

Where a closed circuit (heating system etc) has been categorised by the water undertaker as a fluid category 3 risk, the installation of a compliant double check valve on the fill point connection to the supply/distribution pipe may be considered as acceptable backflow protection.

Where a fill point connection incorporates a “flexible hose connection”, when not in use it is good practice for the hose to be completely disconnected and removed. However, a partial disconnection, that is to say only detaching one end of the hose, may be acceptable providing the disconnection is made between the hose and the backflow prevention device on the supply/distribution pipe.

Please note: if the water undertaker has concerns about the likelihood of contamination, or the suitability of a double check valve - for example due either to age, operating temperature or pressure fluctuations – under schedule 2 paragraph 15(4) they can require the installation of additional backflow protection.

Acceptable safety devices include:

Temperature relief valves

Temperature control arrangements such as non-self-resetting energy cut outs and cylinder thermostats (interlocked to prevent flow from the primary circuit).

Combined temperature and pressure relief valves

Pressure reducing valves

Expansion vessels installed in combination with expansion relief valves. For further information, including advice about safety device arrangements for different methods of heating, please refer to the relevant version of the Building Regulations.

All safety devices must comply with the requirements of regulation/byelaw 4(1). Examples of appropriate British Standards are given in the guidance to part G of the Building Regulations.

All water fittings must be suitable for the circumstances in which they are used. In addition to the normal system operating temperatures and pressures consideration should be given to the suitability of components for use at elevated temperatures likely to be encountered under fault conditions.

The safety arrangements installed on a water heater used to heat water for domestic applications should prevent the temperature exceeding 100o C.

The suitability of safety arrangements for other applications, for example industrial processes will be assessed on a case by case basis.

Where the source of heat energy cannot be relied upon in all circumstances to achieve the required minimum temperature to address concerns about microbiological growth an additional heat source should be available.

Any discharge from a hot water system safety device should be safe and conspicuous. Where a discharge is made via a tundish it should conform to the applicable British Standard or equivalent. For further information please refer to the relevant version of the Building Regulations.

Advice regarding the sizing of hot water system vent pipes can be found in the guidance to part G of the Building Regulations, BS EN 806 and BS 8558.

All hot water systems must be capable of accommodating expansion. There are various ways to do this including:

(a) Secondary hot water systems only

The water fittings regulations/byelaws permit accommodation within the secondary hot water system, of thermal expansion from unvented water heaters (with the exception of instantaneous water heaters with a capacity less than 15 litres).

This is however only allowed if:

The expanded water does not increase the temperature of the water in the supply pipe to in excess of 25°C in England and Wales 20°C in Scotland and Northern Ireland. As this may result in waste or impact on wholesomeness.

Both the expanded water plus any displacement can be accommodated within the supply pipe. It is not permissible for water displaced as a result of accommodating expansion to backflow into the pipework owned by the local water undertaker.

(b) Primary feed and expansion cisterns

To prevent waste the preset water level for expansion cisterns or combined feed and expansion cisterns should accommodate at least 4% of the total volume in the primary (heating) system circuit before discharging through the overflow or warning pipe.

(c) Expansion vessels

To address contamination concerns associated with stagnation and particulate accumulation it is recommended expansion vessels be installed so as to avoid localised low turnover (stagnation).

Specifically, they be installed securely in the vertical so that the water fitting is:

bottom fed and upright

the connecting pipework to the fitting

rises continuously

is kept to a minimum

sized correctly for the system

designed to ensure an adequate turnover of water within the expansion vessel.

Please note: Where an expansion vessel is used an expansion valve which operates at an appropriate operating pressure must be fitted to ensure water discharges safely and conspicuously in the event of a malfunction. To prevent waste the expansion valve must automatically close after a discharge.

No intervening valves should be installed between the expansion vessel, expansion valve and hot water heater/storage.

Protecting public health by minimising the risk of contaminated fluids coming into contact with water to be used for domestic purposes is a key objective of the water fittings regulations/byelaws. In keeping with this principle, where there is considered to be a contamination risk this is either mitigated by avoidance or safeguards such as installing backflow protection.

Depending upon their design and fluids involved, heating and cooling systems which make use of heat recovery or exchange, including but not limited to those listed below, pose different potential contamination risks.

Heat exchangers linking primary and secondary systems

Ground source and air source heat pumps

Chillers

Calorifiers

Heat recovery products utilising the heat energy in wastewater

In enforcing the regulations/byelaws water undertakers take a risk based and proportionate approach. Enforcement policies cite the need to be transparent, consistent, targeted and accountable.

Mindful of the need to ensure sufficient safeguards are in place to address the possibility of drinking water supplies coming into contact with fluids which are not considered to be wholesome, in determining whether water fittings/systems making use of heat recovery or exchange are compliant with regulation/byelaw 4(1) the following factors will be taken into consideration. Please note decisions will be taken on a case by case basis.

The actual fluid categories of the fluids within the system.

How readily identifiable any potential integrity failure of the water fitting/system would be.

Whether the fitting design meets the requirements for single or double wall separation specified in BS EN 1717.

Please note: pipework supplying water for domestic use should be external to and separate from wastewater pipework. It should not be sealed within a fitting which conveys wastewater unless the local water undertaker has been notified and given consent.

The purpose of the water fittings regulations/byelaws is to prevent contamination, waste, misuse, undue consumption and erroneous measurement. There are a number of regulators responsible for enforcement of safety requirements including the Health and Safety Executive, Trading Standards and local authorities. Satisfying the water fittings regulations/byelaws does not guarantee compliance with the regulations these bodies enforce.

We use cookies to give you the best possible experience with Water Regs UK. Some are essential to provide website functions and ensure the website is secure. We also use cookies to help us understand how people use the site and to make improvements. Click "Accept All" to enable recommended settings or click "Manage cookies" to adjust your settings. For more details, see our Cookie Policy.