Installation: Requirements & Guidance

Regulation /Byelaw 4(3) & (4)

If you cannot find the information you require on our website, please contact the local water undertaker. Contact details can be found here.

Regulations / Byelaws

England & Wales: Water Supply (Water Fittings) Regulations (1999) (revised)

(3) Every water fitting shall comply with the requirements of Schedule 2 to these Regulations as it applies to that fitting.

(4) Where any requirement of Schedule 2 relates to a water system, every water fitting which forms part of that system shall be fitted or, as the case may be, altered or replaced so as to comply with that requirement.

Scotland: Water Supply (Water Fittings) (Scotland) Byelaws (2014)

(3) Without prejudice to paragraph (2), every water fitting must comply with the requirements of Schedule 2 as it applies to that fitting.

(4) Where any requirement of Schedule 2 relates to a water system, every water fitting which forms part of that system must be fitted or, as the case may be, altered or replaced so as to comply with that requirement.

Northern Ireland: The Water Supply (Water Fittings) Regulations (Northern Ireland) 2009 (revised)

(3) Every water fitting shall comply with the requirements of Schedule 2 as it applies to that fitting.

(4) Where any requirement of Schedule 2 relates to a water system, every water fitting which forms part of that system shall be fitted or, as the case may be, altered or replaced so as to comply with that requirement.

Schedule 2 requirements

Paragraph 2 (Regulations in England, Wales and Northern Ireland)

(1) Subject to sub-paragraph (2) below, no material or substance, either alone or in combination with any other material or substance or with the contents of any water fitting of which it forms a part, which causes or is likely to cause contamination of water shall be used in the construction, installation, renewal, repair or replacement of any water fitting which conveys or receives, or may convey or receive, water supplied for domestic or food production purposes.

(2) This requirement does not apply to a water fitting downstream of a terminal fitting supplying wholesome water where–

(a) the use to which the water downstream is put does not require wholesome water; and

(b) a suitable arrangement or device to prevent backflow is installed.

Paragraph 2 (Byelaws in Scotland)

(1) No material or substance (either alone or in combination with any other material or substance or with the contents of any water fitting of which it forms a part) which causes or is likely to cause contamination of water is to be used in the construction, installation, renewal, repair or replacement of any water fitting which conveys or receives, or may convey or receive, water supplied for domestic purposes or food production purposes.

(2) Sub-paragraph (1) does not apply to a water fitting downstream of a terminal fitting supplying wholesome water where—

(a) the use to which the water downstream is put does not require wholesome water; and

(b) a suitable arrangement or device to prevent backflow is installed.

Guidance to Paragraph 2

Providing appropriate and adequate backflow protection against the highest level of risk downstream is installed, an installation not used to supply water for drinking, bathing, food preparation or cooking purposes is exempt from complying with schedule 2 paragraph 2(1).

Please note the backflow protection required needs to be assessed by the local water undertaker and other requirements of the water fittings regulations/byelaws continue to apply.

Paragraph 3 (Regulations in England, Wales and Northern Ireland)

Every water fitting shall -

(a) be immune to or protected from corrosion by galvanic action or by any other process which is likely to result in contamination or waste of water; and

(b) be constructed of materials of such strength and thickness as to resist damage from any external load, vibration, stress or settlement, pressure surges, or temperature fluctuation to which it is likely to be subjected.

Paragraph 3 (Byelaws in Scotland)

Every water fitting shall be -

(a) immune to or protected from corrosion by galvanic action or by any other process which is likely to result in contamination or waste of water; and

(b) constructed of materials of such strength and thickness as to resist damage from any external load, vibration, stress or settlement, pressure surges, or temperature fluctuation to which it is likely to be subjected.

Guidance Paragraph 3

All water fittings should be resistant to corrosion.

In the case of backflow prevention devices and any water fittings which are not going to be readily accessible in addition to being corrosion resistant they should be manufactured from materials which are not susceptible to dezincification. For example, gunmetal or CR brass.

Establishing whether a water fitting is suitable for installation is dependent upon a number of factors including but not limited to:

Water fittings must be of an appropriate quality and standard

System design, things considered include but are not limited to compatibility

with other water fittings within a plumbing system (e.g the potential for galvanic action)

system operational parameters (e.g. the maximum* and minimum pressure, temperature and flow the systems will be operating at)

Location specific factors, things considered include but are not limited to:

the environment (e.g. ground or airborne contamination, the risk of frost damage, corrosion or dezincification, external load and ground movement)

product installation requirements and/or constraints (e.g. installed where light is excluded or only above ground)

installation backflow risks (e.g. the need for backflow protection to be installed)

Requirements of schedule 2 as applicable.

* Please note all water fittings must be capable of withstanding an internal water pressure of not less than 1½ times the maximum pressure it will be subject to in operation.

Paragraph 4 (Regulations in England, Wales and Northern Ireland)

Every water fitting shall–

(a) be watertight;

(b) be so constructed and installed as to–

(i) prevent ingress by contaminants, and

(ii) inhibit damage by freezing or any other cause;

(c) be so installed as to minimise the risk of permeation by, or deterioration from contact with, any substance which may cause contamination; and

(d) be adequately supported.

Paragraph 4 (Byelaws in Scotland)

Every water fitting shall be –

(a) watertight;

(b) constructed and installed so as to–

(i) prevent ingress by contaminants, and

(ii) inhibit damage by freezing or any other cause;

(c) installed so as to minimise the risk of permeation by, or deterioration from contact with, any substance which may cause contamination; and

(d) adequately supported.

Guidance Paragraph 4

To be accepted as being of an appropriate quality and standard a water fitting should:

comply with regulation 4(1)(a)

be designed, constructed and installed so that it does not leak

be suitable for the environment in which it is to be installed

be installed in a manner which protects it from ingress, permeation or damage

adequately supported.

Useful sources of information include Regulation 4(1)(a) compliance guidance, BS 6920 Compliance OverviewBS EN 806, and BS 8558.

Potential contamination risks to plumbing systems include but are not limited to:

Environmental contaminants passing through the body of water fittings. For example, hydrocarbons in soil permeating through plastic pipework.

Ingress of fluids, insects or animals through worn, damaged or incorrectly installed plumbing fittings, warning pipes and overflows. For example, a drain tap installed where it could become submerged in fluids such as groundwater; warning pipes discharging directly into sewerage pipes; rainwater or insects accessing a storage cistern via an unshrouded or unscreened weir overflow.

Warming of water. For example, storage tanks or pipework installed without adequate insulation.

Stagnation. For example, due to oversizing of storage systems, inconsistent demand or redundant ‘deadlegs’ pipework.

Use of non-compliant water fittings and materials. For example, lead solder used on wholesome water systems.

Backflow. For example, where no or incorrect backflow protection is installed.

Potential sources of damage to water systems include but are not limited to:

Pipework laid at too shallow a depth being damaged by vehicles driving over it or flexing in as a consequence of ground movement.

Freezing. For example, due to installation outside the thermal envelope or insufficient insulation.

Changes in the integrity of plumbing fittings due to exposure to high temperatures, excessive pressures, ground or airborne substances, sunlight and/or fittings or materials which are incompatible. For example, galvanic action.

Lack of inspection and/or maintenance

Vandalism

Paragraph 5 (Regulations in England, Wales and Northern Ireland)

Every water fitting shall be capable of withstanding an internal water pressure not less than 1½ times the maximum pressure to which that fitting is designed to be subjected in operation.

Paragraph 5 (Byelaws In Scotland)

Every water fitting must be capable of withstanding an internal water pressure not less than 1½ times the maximum pressure to which that fitting is designed to be subjected in operation.

Paragraph 6 (Regulations in England, Wales and Northern Ireland)

No water fitting shall be installed, connected or used which is likely to have a detrimental effect on the quality or pressure of water in a water main or other pipe of a water undertaker or water supply licensee.

Paragraph 6 (Byelaws in Scotland)

No water fitting is to be installed, connected or used which is likely to have a detrimental effect on the quality or pressure of water in a water main or other pipe of Scottish Water.

Paragraph 7 (Regulations in England, Wales and Northern Ireland)

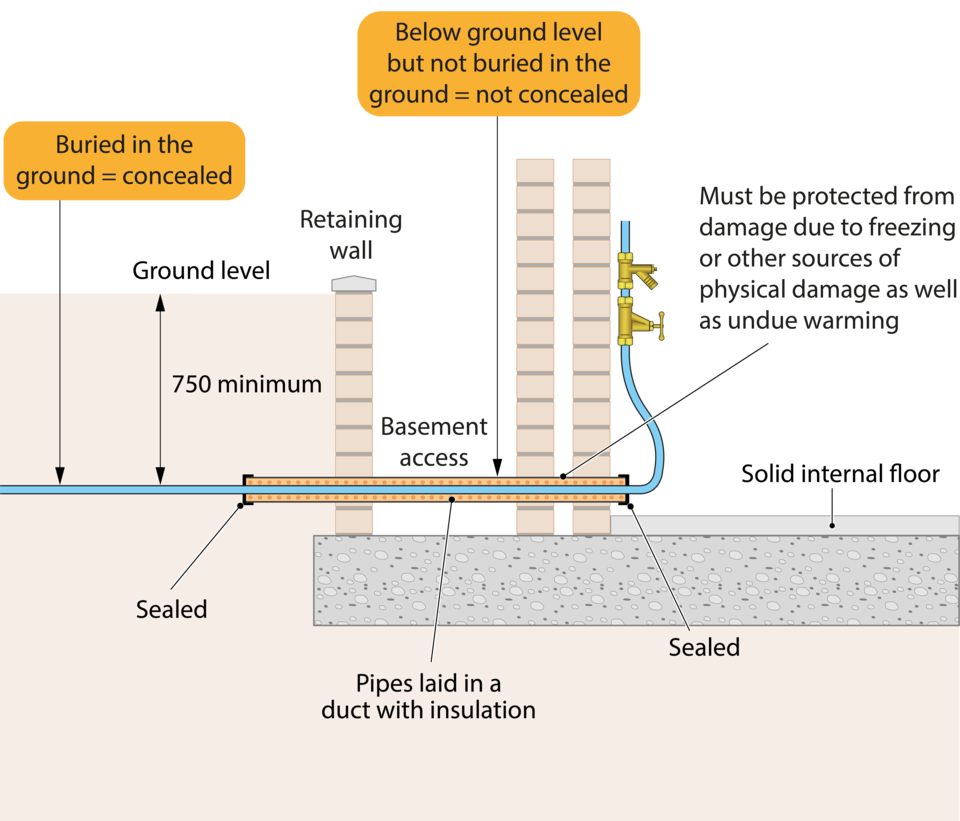

(1) No water fitting shall be embedded in any wall or solid floor.

(2) No fitting which is designed to be operated or maintained, whether manually or electronically, or which consists of a joint, shall be a concealed water fitting.

(3) Any concealed water fitting or mechanical backflow prevention device, not being a terminal fitting, shall be made of gunmetal, or another material resistant to dezincification.

(4) Any water fitting laid below ground level shall have a depth of cover sufficient to prevent water freezing in the fitting.

(5) In this paragraph “concealed water fitting” means a water fitting which–

(a) is installed below ground;

(b) passes through or under any wall, footing or foundation;

(c) is enclosed in any chase or duct; or

(d) is in any other position which is inaccessible or renders access difficult.

Paragraph 7 (Byelaws Scotland)

(1) No water fitting is to be embedded in any wall or solid floor.

(2) No fitting which is designed to be operated or maintained, whether manually or electronically, or which consists of a joint, is to be a concealed water fitting.

(3) Any concealed water fitting or mechanical backflow prevention device, not being a terminal fitting, shall be made of gunmetal, or another material resistant to dezincification.

(4) Any water fitting laid below ground level shall have a depth of cover sufficient to prevent water freezing in the fitting.

(5) In sub-paragraphs (2) and (3) “concealed water fitting” means a water fitting which–

(a) is installed below ground;

(b) passes through or under any wall, footing or foundation;

(c) is enclosed in any chase or duct; or

(d) is in any other position which is inaccessible or renders access difficult.

Guidance Paragraph 7

Joints on concealed pipework are likely to lose their integrity over time and therefore should only be considered where unavoidable.

All water fittings should be resistant to corrosion. In the case of backflow prevention devices and any water fittings which are not going to be readily accessible in addition to being corrosion resistant they should be manufactured from materials which are not susceptible to dezincification. For example, gunmetal or CR brass.

To prevent waste there needs to be provision to access any joints or water fittings which require maintenance, such as backflow prevention devices, valves which control the flow and any other operational fitting.

Water fittings considered to be concealed include those:

Buried in the ground

Installed below or embedded in floors

Installed in or behind wall finishes

Water fittings considered not to be concealed include those:

Installed below ground but not buried, such as in a chamber or basement room

Installed below floors or in walls which can be readily accessed

Paragraph 8 (Regulations in England, Wales and Northern Ireland)

No water fitting shall be installed in such a position, or pass through such surroundings, that it is likely to cause contamination or damage to the material of the fitting or the contamination of water supplied by the water undertaker or water supply licensee.

Paragraph 8 (Byelaws in Scotland)

No water fitting is to be installed in such a position, or pass through such surroundings, that it is likely to cause contamination or damage to the material of the fitting or the contamination of water supplied by Scottish Water.

Guidance Paragraph 8

When designing a compliant plumbing system a number of factors need to be considered, including but not limited to:

Avoiding the risk of contamination or damage resulting from the environment in which the system is to be installed or due to the design itself.

The required and attainable supply pressure and other operational parameters

User expectations and whether these are achievable

Suitability of water fittings for use

Providing appropriate, adequate backflow protection.

Water efficiency

Limiting waste.

Paragraph 9 (Regulations in England and Wales)

Any pipe supplying cold water for domestic purposes to any tap shall be so installed that, so far as is reasonably practicable, the water is not warmed above 25°C.

Paragraph 9 (Byelaws in Scotland)

Any pipe supplying cold water for domestic purposes to any tap shall be so installed that, so far as is reasonably practicable, the water is not warmed above 20°C.

Paragraph 9 (Regulations in Northern Ireland)

Any pipe supplying cold water for domestic purposes to any tap shall be so installed that, so far as is reasonably practicable, the water is not warmed above 20°C.

Guidance Paragraph 9

To minimise the risk of contamination resulting from microbial growth and wastage due to taps left to run, cold water distribution systems should be designed and installed to maintain a temperature not exceeding 20oC.

Paragraph 10 (Regulations in England, Wales and Northern Ireland)

(1) Every supply pipe or distributing pipe providing water to separate premises shall be fitted with a stop valve conveniently located to enable the supply to those premises to be shut off without shutting off the supply to any other premises.

(2) Where a supply pipe or distributing pipe provides water in common to two or more premises, it shall be fitted with a stop valve to which each occupier of those premises has access.

Paragraph 10 (Byelaws in Scotland)

(1) Every supply pipe or distributing pipe providing water to separate premises must be fitted with a stop valve conveniently located to enable the supply to those premises to be shut off without shutting off the supply to any other premises.

(2) Where a supply pipe or distributing pipe provides water in common to two or more premises, it must be fitted with a stop valve to which each occupier of those premises has access.

Paragraph 11 (Regulations in England, Wales and Northern Ireland)

Water systems shall be capable of being drained down and be fitted with an adequate number of servicing valves and drain taps so as to minimize the discharge of water when water fittings are maintained or replaced. A sufficient number of stop valves shall be installed for isolating parts of the pipework.

Paragraph 11 (Byelaws in Scotland)

(1) Water supply systems must be capable of being drained down and be fitted with an adequate number of servicing valves and drain taps so as to minimize the discharge of water when water fittings are maintained or replaced.

(2) A sufficient number of stop valves must be installed for isolating parts of the pipework.

Guidance Paragraph 11

Servicing valves are used to isolate individual water fittings. Their purpose is to minimise waste when individual water fittings are maintained or replaced.

Stop valves isolate an area or 'zone' within a premises.

Paragraph 15 (Regulations in England and Wales)

(1) Subject to the following provisions of this paragraph, every water system shall contain an adequate device or devices for preventing backflow of fluid from any appliance, fitting or process from occurring.

(2) Paragraph (1) does not apply to–

(a) a water heater where the expanded water is permitted to flow back into a supply pipe, or

(b) a vented water storage vessel supplied from a storage cistern,

where the temperature of the water in the supply pipe or the cistern does not exceed 25°C.

(3) The device used to prevent backflow shall be appropriate to the highest applicable fluid category to which the fitting is subject downstream before the next such device.

(4) Backflow prevention shall be provided on any supply pipe or distributing pipe–

(a) where it is necessary to prevent backflow between separately occupied premises, or

(b) where the water undertaker has given notice for the purposes of this Schedule that such prevention is needed for the whole or part of any premises.

(5) A backflow prevention device is adequate for the purposes of paragraph (1) if it is in accordance with a specification approved by the regulator for the purposes of this Schedule.

Paragraph 15 (Byelaws in Scotland)

(1) Subject to sub-paragraphs (2) to (5), every water system must contain an adequate device or devices for preventing backflow of fluid from any appliance, fitting or process from occurring.

(2) Sub-paragraph (1) does not apply to—

(a) a water heater where the expanded water is permitted to flow back into a supply pipe; or

(b) a vented water storage vessel supplied from a storage cistern, where the temperature of the water in the supply pipe or the cistern does not exceed 20°C.

(3) The device used to prevent backflow must be appropriate to the highest applicable category of fluid in Schedule 1 to which the fitting is subject downstream before the next such device.

(4) Backflow prevention shall be provided on any supply pipe or distributing pipe— (a) where it is necessary to prevent backflow between separately occupied premises; or (b) where Scottish Water has given notice for the purposes of this Schedule that such prevention is needed for the whole or part of any premises.

(5) A backflow prevention device is adequate for the purposes of sub-paragraph (1) if it conforms to a specification approved for the purposes of paragraph 15(1) of Schedule 2 to the Water Supply (Water Fittings) Regulations 1999 (pursuant to sub-paragraph (5) of that paragraph).

Paragraph 15 (Regulations in Northern Ireland)

(1) Subject to the following provisions of this paragraph, every water system shall contain an adequate device or devices for preventing backflow of fluid from any appliance, fitting or process from occurring.

(2) Paragraph (1) does not apply to—

(a) a water heater where the expanded water is permitted to flow back into a supply pipe, or

(b) a vented water storage vessel supplied from a storage cistern,

where the temperature of the water in the supply pipe or the cistern does not exceed 20°C.

(3) The device used to prevent backflow shall be appropriate to the highest applicable fluid category to which the fitting is subject downstream before the next such device.

(4) Backflow prevention shall be provided on any supply pipe or distributing pipe—

(a )where it is necessary to prevent backflow between separately occupied premises, or

(b) where the water undertaker has given notice for the purposes of this Schedule that such prevention is needed for the whole or part of any premises.

(5) A backflow prevention device is adequate for the purposes of paragraph (1) if it is in accordance with a specification approved by the Secretary of State or the National Assembly of Wales under The Water Supply (Water Fittings) Regulations 1999.

Guidance Paragraph 15

Guidance to paragraph 15(1)

In this paragraph reference to devices includes backflow protection arrangements.

Guidance to paragraph 15(2)

Thermal expansion from unvented water heaters (with the exception of instantaneous water heaters with a capacity less than 15 litres) may be accommodated within the secondary hot water system. However this is only allowed if:

The expanded water does not increase the temperature of the water in the supply pipe to in excess of 25°C in England and Wales 20°C in Scotland and Northern Ireland. As this may result in waste or impact on wholesomeness.

Both the expanded water plus any displacement can be accommodated within the supply pipe. It is not permissible for water displaced as a result of accommodating expansion to backflow into the pipework owned by the local water undertaker.

Guidance to paragraph 15(3)

The lowest level of backflow protection required as point of use protection must have a backflow protection rating which is at least equivalent to the highest fluid category of any downstream fluids an installation will be subjected to.

Guidance to paragraph 15(4)

Where a water undertaker considers there to be a likelihood, which cannot be reasonably ignored, of contamination by backflow within a premises or the wider network they can require additional backflow protection. In some circumstances as an alternative to this a higher level of point of use backflow protection may be permitted.

Paragraph 16 (Regulations in England, Wales and Northern Ireland)

(1) Every pipe supplying water connected to a storage cistern shall be fitted with an effective adjustable valve capable of shutting off the inflow of water at a suitable level below the overflowing level of the cistern.

(2) Every inlet to a storage cistern, combined feed and expansion cistern, WC flushing cistern or urinal flushing cistern shall be fitted with a servicing value on the inlet pipe adjacent to the cistern.

(3) Every storage cistern, except one supplying water to the primary circuit of a heating system, shall be fitted with a servicing valve on the outlet pipe.

(4) Every storage cistern shall be fitted with–

(a) an overflow pipe, with a suitable means of warning of an impending overflow, which excludes insects;

(b) a cover positioned so as to exclude light and insects; and

(c) thermal insulation to minimize freezing or undue warming.

(5) Every storage cistern shall be so installed as to minimize the risk of contamination of stored water. The cistern shall be of an appropriate size, and the pipe connections to the cistern shall be so positioned, as to allow free circulation and to prevent areas of stagnant water from developing.

Paragraph 16 (Byelaws in Scotland)

(1) Every pipe supplying water connected to a storage cistern must be fitted with an effective adjustable valve capable of shutting off the inflow of water at a suitable level below the overflowing level of the cistern.

(2) Every inlet to a storage cistern, combined feed and expansion cistern, WC flushing cistern or urinal flushing cistern must be fitted with a servicing value on the inlet pipe adjacent to the cistern.

(3) Every storage cistern, except one supplying water to the primary circuit of a heating system, must be fitted with a servicing valve on the outlet pipe.

(4) Every storage cistern must be fitted with–

(a) an overflow pipe, with a suitable means of warning of an impending overflow, which excludes insects;

(b) a cover positioned so as to exclude light and insects; and

(c) thermal insulation to minimize freezing or undue warming.

(5) Every storage cistern must be so installed as to minimize the risk of contamination of stored water. The cistern must be of an appropriate size, and the pipe connections to the cistern shall be so positioned, as to allow free circulation and to prevent areas of stagnant water from developing.

Guidance Paragraph 16

For the water stored in the cistern to remain wholesome it is important to minimise the risk of contamination. Key to this is making sure the water is stored for as short a period as possible. This is achieved through a combination of design and maintenance features and correctly sizing the cistern to ensure the regular turnover of the stored water and avoid stagnation as well as any deterioration of water quality.

Factors which should be considered when sizing a cistern include occupancy (intended and actual) and usage. Suggestions for storage capacity are given in BS EN 806-2

Paragraph 17 (Regulations in England, Wales and Northern Ireland)

(1) Every unvented water heater, not being an instantaneous water heater with a capacity not greater than 15 litres, and every secondary coil contained in a primary system shall–

(a) be fitted with a vent pipe, a temperature control device, a temperature relief device and a combined temperature pressure and relief valve; or

(b) be capable of accommodating expansion within the secondary hot water system.

(2) An expansion valve shall be fitted with provision to ensure that water is discharged in a correct manner in the event of a malfunction of the expansion vessel or system.

Paragraph 17 (Byelaws in Scotland)

(1) Every unvented water heater, not being an instantaneous water heater with a capacity not greater than 15 litres, and every secondary coil contained in a primary system must–

(a) be fitted with a vent pipe, a temperature control device, a temperature relief device and a combined temperature pressure and relief valve; or

(b) be capable of accommodating expansion within the secondary hot water system.

(2) An expansion valve shall be fitted with provision to ensure that water is discharged in a correct manner in the event of a malfunction of the expansion vessel or system.

(3) Without prejudice to the general application of the requirements sub- paragraphs (1) and (2), those requirements are to be deemed to have been met if alternative safety devices are fitted—

(a) with at least an equivalent degree of safety in preventing the temperature of stored water exceeding 100°C; and

(b) which comply with the Building (Scotland) Regulations 2004(j) (including, in particular, paragraph 4.9 of Schedule 5 to those Regulations) and the associated guidance having effect in accordance with section 4(1) and (2) of the Building (Scotland) Act 2003(k).

Guidance Paragraph 17

All unvented hot water heaters must be capable of accommodating expansion or fitted with adequate safety arrangement to prevent systems overheating and over pressurising.

Accommodation of expansion

The water fittings regulations/byelaws permit accommodation within the secondary hot water system, of thermal expansion from unvented water heaters (with the exception of instantaneous water heaters with a capacity less than 15 litres).

This is however only allowed if:

The expanded water does not increase the temperature of the water in the supply pipe to in excess of 25°C in England and Wales 20°C in Scotland and Northern Ireland. As this may result in waste or impact on wholesomeness.

Both the expanded water plus any displacement can be accommodated within the supply pipe. It is not permissible for water displaced as a result of accommodating expansion to backflow into the pipework owned by the local water undertaker.

Acceptable safety devices include:

Temperature relief valves

Temperature control arrangements such as non-self-resetting energy cut outs and cylinder thermostats (interlocked to prevent flow from the primary circuit).

Combined temperature and pressure relief valves

Pressure reducing valves

Expansion vessels installed in combination with expansion relief valves.

For further information, including advice about safety device arrangements for different methods of heating, please refer to the relevant version of the Building Regulations.

The water fittings regulations/byelaws permit accommodation within the secondary hot water system, of thermal expansion from unvented water heaters (with the exception of instantaneous water heaters with a capacity less than 15 litres).

Please note: in England, Wales and Scotland this requirement is met by safety devices which satisfy the relevant Building Regulations.

Paragraph 18 (Regulations in England, Wales and Northern Ireland)

Appropriate vent pipes, temperature control devices and combined temperature pressure and relief valves shall be provided to prevent the temperature of the water within a secondary hot water system from exceeding 100°C.

Paragraph 18 (Byelaws in Scotland)

Appropriate vent pipes, temperature control devices and combined temperature pressure and relief valves must be provided to prevent the temperature of the water within a secondary hot water system from exceeding 100°C.

Guidance Paragraph 18

The safety arrangements installed on a water heater used to heat water for domestic applications should prevent the temperature exceeding 100oC.

The suitability of safety arrangements for other applications, for example industrial processes will be assessed on a case by case basis.

Where the source of heat energy cannot be relied upon in all circumstances to achieve the required minimum temperature to address concerns about microbiological growth an additional heat source should be available.

Please note: in England, Wales and Scotland this requirement is met by safety devices which satisfy the relevant Building Regulations.

Paragraph 19 (Regulations in England, Wales and Northern Ireland)

Discharges from temperature relief valves, combined temperature and pressure and relief valves and expansion valves shall be made in a safe and conspicuous manner.

Paragraph 19 (Byelaws in Scotland)

Discharges from temperature relief valves, combined temperature and pressure and relief valves and expansion valves must be made in a safe and conspicuous manner.

Paragraph 20 (Regulations in England, Wales and Northern Ireland)

(1) No vent pipe from a primary circuit shall terminate over a storage cistern containing wholesome water for domestic supply or for supplying water to a secondary system.

(2) No vent pipe from a secondary circuit shall terminate over any combined feed and expansion cistern connection to a primary circuit.

Paragraph 20 (Byelaws in Scotland)

(1) No vent pipe from a primary circuit is to terminate over a storage cistern containing wholesome water for domestic supply or for supplying water to a secondary system.

(2) No vent pipe from a secondary circuit is to terminate over any combined feed and expansion cistern connection to a primary circuit.

(3) In sub-paragraph (1) “secondary system” means an assembly of water fittings comprising the cold feed pipe, any hot water storage vessel, water heater and pipework from which hot water is conveyed to all points of draw-off.

Guidance Paragraph 20

In addition to the above requirements, where a cold water cistern supplying water for drinking, bathing, washing, cooking and other sanitary purposes, is used to accommodate the expansion of water within a secondary (hot water) system, the expanded water should not raise the temperature of the stored water to more than 25°C in England and Wales, 20°C in Scotland and Northern Ireland.

Paragraph 21 (Regulations in England, Wales and Northern Ireland)

Every expansion cistern or expansion vessel, and every cold water combined feed and expansion cistern connected to a primary circuit, shall be such as to accommodate any expansion water from that circuit during normal operation.

Paragraph 21 (Byelaws in Scotland)

Every expansion cistern or expansion vessel, and every cold water combined feed and expansion cistern connected to a primary circuit, must be such as to accommodate any expansion water from that circuit during normal operation.

Paragraph 22 (Regulations in England, Wales and Northern Ireland)

(1) Every expansion valve, temperature relief valve or combined temperature and pressure relief valve connected to any fitting or appliance shall close automatically after a discharge of water.

(2) Every expansion valve shall–

(a) be fitted on the supply pipe close to the hot water vessel and without any intervening valves; and

(b) only discharge water when subjected to a water pressure of not less than 0.5 bar (50 kPa) above the pressure to which the hot water vessel is, or is likely to be, subjected in normal operation.

Paragraph 22 (Byelaws in Scotland)

(1) Every expansion valve, temperature relief valve or combined temperature and pressure relief valve connected to any fitting or appliance must close automatically after a discharge of water.

(2) Every expansion valve must–

(a) be fitted on the supply pipe close to the hot water vessel and without any intervening valves; and

(b) only discharge water when subjected to a water pressure of not less than 0.5 bar (50 kPa) above the pressure to which the hot water vessel is, or is likely to be, subjected in normal operation.

Paragraph 23 (Regulations in England, Wales and Northern Ireland)

(1) A temperature relief valve or combined temperature and pressure relief valve shall be provided on every unvented hot water storage vessel with a capacity greater than 15 litres.

(2) the valve shall–

(a) be located directly on the vessel in an appropriate location, and have a sufficient discharge capacity, to ensure that the temperature of the stored water does not exceed 100°C; and

(b) only discharge water at below its operating temperature when subjected to a pressure of not less than 0.5 bar (50 kPa) in excess of the greater of the following–

(i) the maximum working pressure in the vessel in which it is fitted, or

(ii) the operating pressure of the expansion valve.

(3) In this paragraph “unvented hot water storage vessel” means a hot water storage vessel that does not have a vent pipe to the atmosphere.

Paragraph 23 (Byelaws in Scotland)

(1) A temperature relief valve or combined temperature and pressure relief valve must be provided on every unvented hot water storage vessel with a capacity greater than 15 litres.

(2) The valve must–

(a) be located directly on the vessel in an appropriate location, and have a sufficient discharge capacity, to ensure that the temperature of the stored water does not exceed 100°C; and

(b) only discharge water at below its operating temperature when subjected to a pressure of not less than 0.5 bar (50 kPa) in excess of the greater of the following–

(i) the maximum working pressure in the vessel in which it is fitted, or

(ii) the operating pressure of the expansion valve.

(3) In this paragraph (1) “unvented hot water storage vessel” means a hot water storage vessel that does not have a vent pipe to the atmosphere.

(4) Without prejudice to the general application of the requirements of sub- paragraphs (1) and (2), those requirements are to be deemed to have been met if alternative safety devices are fitted—

(a) with at least an equivalent degree of safety in preventing the temperature of stored water exceeding 100°C; and

(b) which comply with the Building (Scotland) Regulations 2004 (including, in particular, paragraph 4.9 of Schedule 5 to those Regulations) and the associated guidance having effect in accordance with section 4(1) and (2) of the Building (Scotland) Act 2003.

Guidance Paragraph 23

Please note: in England, Wales and Scotland this requirement is met by safety devices which satisfy the relevant Building Regulations.

Paragraph 24 (Regulations in England and Wales )

No supply pipe or secondary circuit shall be permanently connected to a closed circuit for filling a heating system unless it incorporates a backflow prevention device in accordance with a specification approved by the regulator for the purposes of this schedule.

Paragraph 24 (Byelaws in Scotland)

No supply pipe or secondary circuit is to be permanently connected to a closed circuit for filling a heating system unless it incorporates a backflow prevention device which conforms to a specification approved for the purposes of, and pursuant to, paragraph 24 of Schedule 2 to the Water Supply (Water Fittings) Regulations 1999.

Paragraph 24 (Regulations in Northern Ireland)

No supply pipe or secondary circuit shall be permanently connected to a closed circuit for filling a heating system unless it incorporates a backflow prevention device in accordance with a specification approved by the Secretary of State or the National Assembly of Wales under the Water Supply (Water Fittings) Regulations 1999.

Paragraph 25 (Regulations in England and Wales )

(1) Subject to the following provisions of this paragraph–

(a) every water closet pan shall be supplied with water from a flushing cistern, pressure flushing cistern or pressure flushing valve, and shall be so made and installed that after normal use its contents can be cleared effectively by a single flush of water, or, where the installation is designed to receive flushes of different volumes, by the largest of those flushes;

(b) no pressure flushing valve shall be installed–

(i) in a house, or

(ii) in any building not being a house where a minimum flow rate of 1.2 litres per second cannot be achieved at the appliance;

(c) where a pressure flushing valve is connected to a supply pipe or distributing pipe, the flushing arrangement shall incorporate a backflow prevention device consisting of a permanently vented pipe interrupter located not less than 300mm above the spillover level of the WC pan or urinal;

(d) no flushing device installed for use with a WC pan shall give a single flush exceeding 6 litres;

(e) no flushing device designed to give flushes of different volumes shall have a lesser flush exceeding two-thirds of the largest flush volume;

(f) every flushing cistern, other than a pressure flushing cistern, shall be clearly marked internally with an indelible line to show the intended volume of flush, together with an indication of that volume;

(g) a flushing device designed to give flushes of different volumes–

(i)shall have a readily discernible method of actuating the flush at different volumes; and

(ii)shall have instructions, clearly and permanently marked on the cistern or displayed nearby, for operating it to obtain the different volumes of flush;

(h) every flushing cistern, not being a pressure flushing cistern or a urinal cistern, shall be fitted with a warning pipe or with a no less effective device;

(i) every urinal that is cleared by water after use shall be supplied with water from a flushing device which–

(i) in the case of a flushing cistern, is filled at a rate suitable for the installation;

(ii) in all cases, is designed or adapted to supply no more water than is necessary for effective flow over the internal surface of the urinal and for replacement of the fluid in the trap; and

(j) except in the case of a urinal which is flushed manually, or which is flushed automatically by electronic means after use, every pipe which supplies water to a flushing cistern or trough used for flushing a urinal shall be fitted with an isolating valve controlled by a time switch and a lockable isolating valve, or with some other equally effective automatic device for regulating the periods during which the cistern may fill.

(2) Every water closet, and every flushing device designed for use with a water closet, shall comply with a specification approved by the regulator for the purposes of this Schedule.

(3) The requirements of sub-paragraphs (1) and (2) do not apply where faeces or urine are disposed of through an appliance that does not solely use fluid to remove the contents.

(4) The requirement in sub-paragraph (1)(i) shall be deemed to be satisfied–

(a) in the case of an automatically operated flushing cistern servicing urinals which is filled with water at a rate not exceeding–

(i) 10 litres per hour for a cistern serving a single urinal;

(ii) 7.5 litres per hour per urinal bowl or stall, or, as the case may be, for each 700mm width of urinal slab, for a cistern serving two or more urinals;

(b) in the case of a manually or automatically operated pressure flushing valve used for flushing urinals which delivers not more than 1.5 litres per bowl or position each time the device is operated.

(5) Until 1st January 2001 paragraphs (1)(a) and (d) shall have effect as if they provided as follows–

“(a) every water closet pan shall be supplied with water from a flushing cistern or trough of the valveless type which incorporates siphonic apparatus;”

“(d) no flushing device installed for use with a WC pan shall give a single flush exceeding 7.5 litres;”.

(6) Notwithstanding sub-paragraph (1)(d) a flushing cistern installed before 1st July 1999 may be replaced by a cistern which delivers a similar volume and which may be either single flush or dual flush; but a single flush cistern may not be so replaced by a dual flush cistern.

(7) In this paragraph–

“pressure flushing cistern” means a WC flushing device that utilises the pressure of water within the cistern supply pipe to compress air and increase the pressure of water available for flushing a WC pan;

“pressure flushing valve” means a self-closing valve supplied with water directly from a supply pipe or a distributing pipe which when activated will discharge a pre-determined flush volume;

“trap” means a pipe fitting, or part of a sanitary appliance, that retains liquid to prevent the passage of foul air; and

“warning pipe” means an overflow pipe whose outlet is located in a position where the discharge of water can readily be seen.

Paragraph 25 (Byelaws in Scotland)

(1) Subject to sub-paragraphs (2) to (5)—

(a) every WC pan must be supplied with water from a flushing cistern, pressure flushing cistern or pressure flushing valve, and must be so made and installed that after normal use its contents can be cleared effectively by a single flush of water, or, where the installation is designed to receive flushes of different volumes, by the largest of those flushes;

(b) no pressure flushing valve is to be installed— (i) in a house; or (ii) in any building not being a house where a minimum flow rate of 1.2 litres per second cannot be achieved at the appliance;

(c) where a pressure flushing valve is connected to a supply pipe or distributing pipe, the flushing arrangement must incorporate a backflow prevention device consisting of a permanently vented pipe interrupter located not less than 150 mm above the spillover level of the WC pan or urinal;

(d) no flushing device installed for use with a WC pan is to give a single flush exceeding 6 litres;

(e) notwithstanding head (d), a flushing cistern installed before these Byelaws come into force may be replaced by a cistern which delivers a similar volume and which may be either single flush or dual flush, but a single flush cistern may not be so replaced by a dual flush cistern;

(f) no flushing device designed to give flushes of different volumes shall have a lesser flush exceeding two-thirds of the largest flush volume;

(g) every flushing cistern, other than a pressure flushing cistern, must be clearly marked internally with an indelible line to show the intended volume of flush, together with an indication of that volume;

(h) a flushing device designed to give flushes of different volumes must have—

(i) a readily discernible method of actuating the flush at different volumes; and

(ii) instructions, clearly and permanently marked on the cistern or displayed nearby, for operating it to obtain the different volumes of flush;

(i) every flushing cistern, not being a pressure flushing cistern or a urinal cistern, must be fitted with a warning pipe or with a no less effective device;

(j) every urinal that is cleared by water after use must be supplied with water from a flushing device which—

(i) in the case of a flushing cistern, is filled at a rate suitable for the installation;

(ii) in all cases, is designed or adapted to supply no more water than is necessary for effective flow over the internal surface of the urinal and for replacement of the fluid in the trap; and

(k) except in the case of a urinal which is flushed manually, or which is flushed automatically by electronic means after use, every pipe which supplies water to a flushing cistern or trough used for flushing a urinal must be fitted with an isolating valve controlled by a time switch and a lockable isolating valve, or with some other equally effective automatic device for regulating the periods during which the cistern may fill.

(2) Every WC, and every flushing device designed for use with a WC, must conform to a specification approved for the purposes of, and pursuant to, paragraph 25(2) of Schedule 2 to the Water Supply (Water Fittings) Regulations 1999.

(3) The requirements of sub-paragraphs (1) and (2) do not apply where faeces or urine are disposed of through an appliance that does not solely use fluid to remove the contents.

(4) The requirement in sub-paragraph (1)(j) is to be deemed to be satisfied—

(a) in the case of an automatically operated flushing cistern servicing urinals, where it is filled with water at a rate not exceeding—

(i) 10 litres per hour, for a cistern serving a single urinal; or

(ii) 7.5 litres per hour per urinal bowl or stall, or, as the case may be, for each 700 mm width of urinal slab, for a cistern serving two or more urinals; and

(b) in the case of a manually or automatically operated pressure flushing valve used for flushing urinals, where it delivers not more than 1.5 litres per bowl or position each time the device is operated.

(5) In this paragraph—

“ pressure flushing cistern” means a WC flushing device that utilises the pressure of water within the cistern supply pipe to compress air and increase the pressure of water available for flushing a WC pan;

“ pressure flushing valve” means a self-closing valve supplied with water directly from a supply pipe or a distributing pipe which when activated will discharge a pre-determined flush volume;

“ trap” means a pipe fitting, or part of a sanitary appliance, that retains liquid to prevent the passage of foul air; and “ warning pipe” means an overflow pipe whose outlet is located in a position where the discharge of water can readily be seen.

Paragraph 25 (Regulations in Northern Ireland)

(1) Subject to the following provisions of this paragraph—

(a) every water closet pan shall be supplied with water from a flushing cistern, pressure flushing cistern or pressure flushing valve, and shall be so made and installed that after normal use its contents can be cleared effectively by a single flush of water, or, where the installation is designed to receive flushes of different volumes, by the largest of those flushes;

(b) no pressure flushing valve shall be installed—

(i) in a house, or

(ii) in any building not being a house where a minimum flow rate of 1.2 litres per second cannot be achieved at the appliance;

(c) where a pressure flushing valve is connected to a supply pipe or distributing pipe, the flushing arrangement shall incorporate a backflow prevention device consisting of a permanently vented pipe interrupter located not less than 300mm above the spillover level of the WC pan or urinal;

(d) no pressure flushing cistern shall be installed unless it incorporates a method of installation approved by the water undertaker or a backflow prevention device approved by the Secretary of State or the National Assembly of Wales under The Water Supply (Water Fittings) Regulations 1999;

(e) no flushing device installed for use with a WC pan shall give a single flush exceeding 6 litres;

(f) no flushing device designed to give flushes of different volumes shall have a lesser flush exceeding two-thirds of the largest flush volume;

(g) every flushing cistern, other than a pressure flushing cistern, shall be clearly marked internally with an indelible line to show the intended volume of flush, together with an indication of that volume;

(h) a flushing device designed to give flushes of different volumes shall have a readily discernible method of actuating the flush at different volumes;

(i) every flushing cistern, not being a pressure flushing cistern or a urinal cistern, shall be fitted with a warning pipe or with a no less effective warning device;

(j) every urinal that is cleared by water after use shall be supplied with water from a flushing device which—

(i) in the case of a flushing cistern, is filled at a rate suitable for the installation;

(ii) n all cases, is designed or adapted to supply no more water than is necessary for effective flow over the internal surface of the urinal and for replacement of the fluid in the trap; and

(k) except in the case of a urinal which is flushed manually, or which is flushed automatically by electronic means after use, every pipe which supplies water to a flushing cistern or trough used for flushing a urinal shall be fitted with an isolating valve controlled by a time switch and a lockable isolating valve, or with some other equally effective automatic device for regulating the periods during which the cistern may fill.

(2) Every water closet, and every flushing device designed for use with a water closet, shall comply with a specification approved by the Secretary of State or the National Assembly of Wales under The Water Supply (Water Fittings) Regulations 1999.

(3) The requirements of sub-paragraphs (1) and (2) do not apply where faeces or urine are disposed of through an appliance that does not solely use fluid to remove the contents.

(4) The requirement in sub-paragraph (1)(j) shall be deemed to be satisfied—

(a) in the case of an automatically operated flushing cistern servicing urinals which is filled with water at a rate not exceeding—

(i)10 litres per hour for a cistern serving a single urinal;

(ii)7.5 litres per hour per urinal bowl or stall, or, as the case may be, for each 700mm width of urinal slab, for a cistern serving two or more urinals;

(b) in the case of a manually or automatically operated pressure flushing valve used for flushing urinals which delivers not more than 1.5 litres per bowl or position each time the device is operated.

(5) Notwithstanding sub-paragraph (1)(e) a flushing cistern installed before 3rd August 2009 may be replaced by a cistern which delivers a similar volume and which may be either single flush or dual flush.

(6) In this paragraph—

“pressure flushing cistern” means a WC flushing device that utilises the pressure of water within the cistern supply pipe to compress air and increase the pressure of water available for flushing a WC pan;

“pressure flushing valve” means a self-closing valve supplied with water directly from a supply pipe or a distributing pipe which when activated will discharge a pre-determined flush volume;

“trap” means a pipe fitting, or part of a sanitary appliance, that retains liquid to prevent the passage of foul air; and

“warning pipe” means an overflow pipe whose outlet is located in a position where the discharge of water can readily be seen.

Paragraph 26 (Regulations in England, Wales and Northern Ireland)

All premises supplied with water for domestic purposes shall have at least one tap conveniently situated for the drawing of drinking water.

Paragraph 26 (Byelaws in Scotland)

All premises supplied with water for domestic purposes must have at least one tap conveniently situated for the drawing of drinking water.

Guidance to Paragraph 26

Where possible drinking water taps should be directly connected to the incoming mains water supply i.e. not via any water fitting which stores, treats or filters the water.

Paragraph 27 (Regulations in England, Wales and Northern Ireland)

A drinking water tap shall be supplied with water from–

(a) a supply pipe;

(b) a pump delivery pipe drawing water from a supply pipe; or

(c) a distributing pipe drawing water exclusively from a storage cistern supplying wholesome water.

Paragraph 27 (Byelaws in Scotland)

A drinking water tap must be supplied with water from—

(a) a supply pipe;

(b) a pump delivery pipe drawing water from a supply pipe; or

(c) a distributing pipe drawing water exclusively from a storage cistern supplying wholesome water.

Guidance to Paragraph 27

Where it is not feasible for a drinking water tap to be directly connected to the incoming mains water supply (for example when fed from a storage cistern or via a water softener or conditioner) the wholesomeness of the water must be maintained to the intended drinking water tap(s), meaning the water fittings used must not adversely affect water quality.

Paragraph 28 (Regulations in England, Wales and Northern Ireland)

(1) Subject to paragraph (2), every bath, wash basin, sink or similar appliance shall be provided with a watertight and readily accessible plug or other device capable of closing the waste outlet.

(2) This requirement does not apply to–

(a) an appliance where the only taps provided are spray taps;

(b) a washing trough or wash basin whose waste outlet is incapable of accepting a plug and to which water is delivered at a rate not exceeding 0.06 litres per second exclusively from a fitting designed or adapted for that purpose;

(c) a wash basin or washing trough fitted with self-closing taps;

(d) a shower bath or shower tray;

(e) a drinking water fountain or similar facility; or

(f) an appliance which is used in medical, dental or veterinary premises and is designed or adapted for use with an unplugged outlet.

Paragraph 28 (Byelaws in Scotland)

(1) Every bath, wash basin, sink or similar appliance must be provided with a watertight and readily accessible plug or other device capable of closing the waste outlet.

(2) Sub-paragraph (1) does not apply to—

(a) an appliance where the only taps provided are spray taps;

(b) a washing trough or wash basin whose waste outlet is incapable of accepting a plug and to which water is delivered at a rate not exceeding 0.06 litres per second exclusively from a fitting designed or adapted for that purpose;

(c) a wash basin or washing trough fitted with self-closing taps;

(d) a shower bath or shower tray;

(e) a drinking water fountain or similar facility; or

(f) an appliance which is used in medical, dental or veterinary premises and is designed or adapted for use with an unplugged outlet.

Paragraph 29 (Regulations in England, Wales and Northern Ireland)

(1) Subject to paragraph (2), clothes washing machines, clothes washer-driers and dishwashers shall be economical in the use of water.

(2) The requirements of this paragraph shall be deemed to be satisfied in the case of machines having a water consumption per cycle of not greater than the following–

(a) for domestic horizontal axis washing machines, 27 litres per kilogram of washload for a standard 60°C cotton cycle;

(b) for domestic washer-driers, 48 litres per kilogram of washload for a standard 60°C cotton cycle;

(c) for domestic dishwashers, 4.5 litres per place setting.

Paragraph 29 (Byelaws in Scotland)

(1) Clothes washing machines, clothes washer-driers and dishwashers must be economical in the use of water.

(2) Sub-paragraph (1) is to be deemed to be satisfied in the case of machines having a water consumption per cycle of not greater than—

(a) for horizontal axis washing machines supplied with water for domestic purposes, 27 litres per kilogram of washload for a standard 60°C cotton cycle;

(b) for washer-driers supplied with water for domestic purposes, 48 litres per kilogram of washload for a standard 60°C cotton cycle; and

(c) for dishwashers supplied with water for domestic purposes, 4.5 litres per place setting.

Paragraph 30 (Regulations in England, Wales and Northern Ireland)

Every pipe which conveys water to a drinking vessel for animals or poultry shall be fitted with–

(a) a float-operated valve, or some other no less effective device to control the inflow of water, which is–

(i) protected from damage and contamination; and

(ii) prevents contamination of the water supply; and

(b) a stopvalve or servicing valve as appropriate.

Paragraph 30 (Byelaws in Scotland)

Every pipe which conveys water to a drinking vessel for animals or poultry must be fitted with—

(a) a float-operated valve, or some other no less effective device to control the inflow of water, which is—

(i) protected from damage and contamination; and

(ii) prevents contamination of the water supply; and

(b) a stop valve or servicing valve as appropriate.

Paragraph 31(Regulations in England, Wales and Northern Ireland)

Every pond, fountain or pool shall have an impervious lining or membrane to prevent the leakage or seepage of water.

Paragraph 31 (Byelaws in Scotland)

Every pond, fountain or pool (which uses, or is to use, water supplied by Scottish Water) must have an impervious lining or membrane to prevent the leakage or seepage of water.

Feedback

To improve this information please give us your feedback >

Disclaimer

Uncontrolled if downloaded. This is informative, non-statutory guidance and intended for general guidance purposes only; it is subject to change.

Compliance with this information should not be relied upon as guaranteeing no enforcement action will be taken by water undertakers. Water Regs UK accepts no liability for loss, indirect or consequential loss arising from or in connection with this guidance document.