District heating systems and the Water Fittings Regulations and Byelaws

Amended July 2024

In this article we will briefly explain the requirements of the Water Fittings Regulations (Byelaws in Scotland) as they apply to these types of systems.

The UK is driving forwards to a low carbon economy where the use of district heating schemes providing central heating or hot water is likely to increase. This is being reinforced by the UK Government and its announcement of a five year, £320m capital support for district heating schemes.

In general any heating or plumbing system which utilises, or provides water from the public supply are subject to the requirements of these regulations and byelaws. They place legal duties on those involved to ensure they are designed, installed, maintained and operated to comply with these regulations and byelaws. Of particular importance is notification, compliant water fittings, avoiding backflow, materials, thermal expansion, heat gain and pipe marking.

Notification

Notification before work starts is an important part of the regulations. It is required for proposed work on any plumbing system in any new premises, or when extending or altering systems in non-domestic premises. For district heating systems it would apply to all parts of the system which is filled or topped up from a public mains supply. For example, from the central plant room, through distribution pipes, to the plumbing systems within the receiving properties.

Some details do differ in Scotland and Northern Ireland and Guidance is available on the WRAS (now Water Regs UK) website.

Compliant water fittings

To ensure that water fittings and plumbing systems are robust and do not cause contamination or waste of water, the regulations specify performance standards which fittings must meet. Designers and installers must ensure that every water fitting used is ‘of an appropriate quality and standard’ (Regulation/Byelaw 4), meaning it must either bear an CE mark1 against an appropriate standard; meet an appropriate British Standard or its equivalent within the European Economic Area; or comply with the performance specification defined by the UK government – the Regulator’s Specifications.

In addition it is important that the materials used don’t cause contamination where parts of fittings are in contact with water required to be ‘wholesome’. This includes drinking water and domestic hot water.

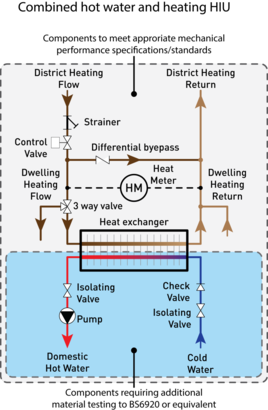

Some heat interface units (HIUs) provide space heating;others domestic hot water generation. This could be from a plate heat exchanger within the HIU, or via primary circuit outlets which feed hot water cylinders within the dwelling. Figure 1 shows two types of HIUs, typical of those found inside properties and where these requirements might apply.

1Conformity to a relevant harmonised EU standard in relation to the Construction Products Regulations (CPR)

Figure 1: Examples of Heat Interface Units

Avoiding backflow - filling and top-up points

An important purpose of the regulations is to prevent the risk of backflow. The most common backflow risks with district heating systems and HIUs arise when using a mains water supply for filling or topping up the closed-loop heating circuits, or in plant rooms where chemical dosing units for water treatment purposes.

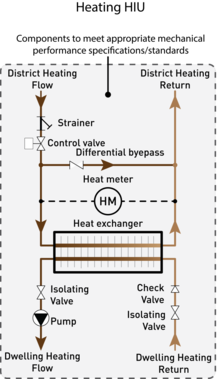

To prevent this, the regulations require use of a backflow prevention device or arrangement giving protection which is rated at the appropriate degree of backflow risk, known as the ‘fluid category’. Water in the closed circuit of a district heating system and in the primary heating circuit in non-domestic premises given in guidance is a fluid category 4 backflow risk. Filling points must be protected by use of suitable backflow prevention device or arrangement rated at fluid category 4 or better. These include a reduced pressure zone (RPZ) valves (a ‘type BA device’), or filling via a cistern with a type AA, AB, AD or AF airgap and an optional booster pump depending on the system. In household systems the fluid categorisation given in guidance is fluid category 3, which allows the use of a temporary connection arrangement as shown in Figure 2. However, it is important to note that a site specific risk assessment of the fluids present, may result in a different fluid category risk compared to general guidance.

Figure 2: Temporary arrangement for using a filling loop with double check valve in domestic premises only

where fluid category 3 is present.

Thermal expansion

When installing pipes, allowance must be made for movement caused by thermal expansion of the pipes, such as in accordance with Part 4 of BS EN 806. This requires allowance for expansion and contraction of the pipes by forming expansion loops, introducing changes of direction to avoid long straight runs or fitting proprietary expansion joints.

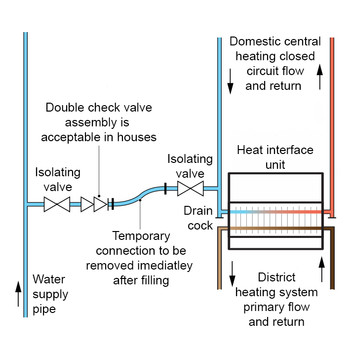

Where water temperatures in fittings alter significantly, for example in heat exchangers, the expansion and contraction of water as it is heated or cooled must be accommodated, usually by means of expansion vessels. These should be designed and installed to avoid localised low turnover (stagnation), leading to the formation of biofilms and/or the accumulation of particulate material.

The expansion vessel should be bottom fed and upright, the connecting pipework to the vessel be rising continuously and be kept to a minimum (see Figure 3). The vessel should be sized correctly for the system and be designed to ensure an adequate turnover of water within it.

District heating systems usually circulate hot water or steam as the means for transferring heat energy. Where pipes carrying high temperature fluids are to be installed near to cold water services, they must be designed and installed so that any heat losses from these systems do not cause warming of the cold water. Within buildings hot pipes should be installed above cold pipes. Outside of buildings where pipes are laid in the ground they must be sufficient distance away from cold water services so that any heat loss is fully dissipated and cannot increase the temperature in cold water services. Specialist advice may need to be sought as there are no set safe minimum distances within water regulations or standards. Therefore each installation will need to be reviewed on its own merits. Localised warming can affect the quality of the cold water, resulting in growth of microorganisms which can cause tastes, odours or give rise to harmful pathogens such as legionella.

Pipe marking

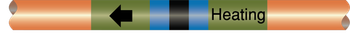

In premises where district heating systems are used both directly for heating and where they provide heat via HIUs, there is a considerable risk that water in the primary circuit, which isn’t wholesome, maybe inadvertently cross-connected directly to the drinking water system during installation or alteration works. Pipe marking helps to prevent this. The regulations require clear identification of pipes that are carrying any water which is not wholesome, such as in the primary heating circuit. There is only one recognised colour-coding scheme and is set out in British Standard BS1710:2014 ‘Specification for identification of pipelines and services’, an example is shown in Figure 4. This standard should be used and where deviations are considered necessary these should be agreed in advance with the local water supplier.

Figure 4: An example of pipe marking to BS 1710.

Figure 4: An example of pipe marking to BS 1710.