Plumbing in appliances

Amended July 2024

Commercial premises often need higher levels of backflow protection for their water-using appliances, such as dishwashers and washing machines. This article provides advice to help identify the right backflow prevention for these appliances.

The design, manufacture and installation of appliances if supplied from the public water mains, come under the scope of the Water Supply (Water Fittings) Regulations in England, Wales and Northern Ireland and under the Water Supply (Water Fittings) Byelaws in Scotland, together referred to as ‘the regulations’.

These appliances must be:

designed and manufactured to be of an appropriate quality and standard;

suitable for the circumstances where they are used; and

installed so that they comply with the regulations.

In addition to the installer, owner and user’s legal duty to comply with the regulations, the licensing of care homes includes a requirement that all relevant legislation must be complied with, which includes the water regulations.

Backflow protection

Appliances must have suitable devices to prevent backflow. Backflow risk from the contents of an appliance is assessed using a system of fluid categories – where fluid category 1 represents drinking quality water and fluid category 5 is the most contaminated. In private domestic dwellings, dishwashers and washing machines are rated as fluid category 3. But in commercial premises there is a higher risk from the same appliances and the backflow risk is rated as fluid category 4, or if healthcare is provided in the premises, as fluid category 5.

The regulations require use of a recognised backflow prevention device. Backflow prevention devices are rated by the level of protection for different fluid categories. The device used must give protection at least as stringent as the assessed risk. For example, an appliance with a fluid category 4 backflow risk must have a backflow prevention device or arrangement of fittings which is rated at least fluid category 4.

Some appliances designed for the commercial sector have fluid category 5 backflow protection built in to protect the water inlets and can be installed without additional requirements. ‘White goods’ intended for the domestic market often do not state what fluid category protection, if any, is inbuilt although some may include fluid category 3 protection.

Where any appliance is used care needs to be taken to identify the backflow protection requirements and ensure that the appliance has the appropriate protection incorporated within the machine or has appropriate backflow protection installed upstream of the appliance.

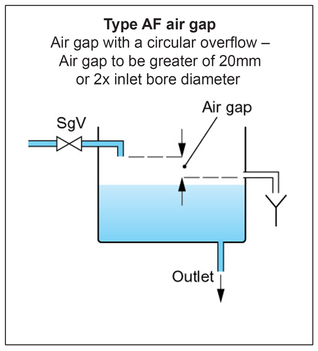

Different backflow devices have different protection ratings. For fluid category 4 protection, appliances can be fed via a ‘break tank’ – a small storage cistern open to atmosphere and containing a Type AF airgap between the inlet and maximum water level. Alternatively a ‘reduced pressure zone valve’ (RPZ valve – a type BA device) can be used to maintain water pressure from the feed pipe. To provide fluid category 5 protection, only a break tank with a Type AA, AB or AD airgap is adequate.

Appliance design and manufacture

The installer has the legal duty to ensure that appliances comply with all aspects of the regulations. When inspecting plumbing systems in new and existing premises, water suppliers’ regulations enforcement staff may ask for evidence of compliance of fittings. People who specify, purchase or install appliances should ask the supplier or manufacturer to provide evidence to confirm that the appliance has been tested and complies with the UK regulations. One approval readily accepted by water suppliers is operated by the Water Regulations Approval Scheme (WRAS) – however other methods to demonstrate compliance are available. Manufacturers submit their products for testing and WRAS assesses the results against the performance criteria and awards ‘WRAS Approved Product’. Up-to-date lists of Approved Products are freely available on the WRAS website.

Usually WRAS Approval is accompanied by requirements for how the appliance should be installed - for example, with an external servicing valve or a given type of backflow prevention device. These ‘Installation Requirements and Notes’ (IRNs) must be complied with for the WRAS Approval to be valid.

Summary

When considering installation of appliances, a risk assessment should be carried out to assess the backflow risk from them and determine the degree of backflow protection required. Before specifying or purchasing appliances, evidence should be gained to show whether the required backflow protection is in-built, and if not, the installer must provide it externally to the appliance.

WRAS Approval is one good way to gain evidence of compliance of the design and manufacture.

And a final thought – in addition to a legal duty for the installer and the user to comply with the regulations, the licensing of care homes includes a requirement that all relevant legislation must be complied with, which includes the water fittings regulations.